- DESCRIPTION

-

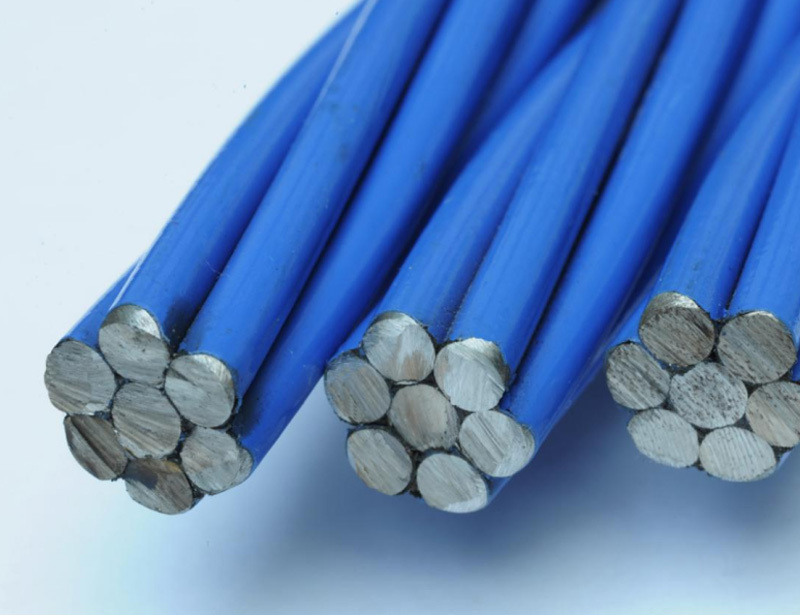

As a kind of pre-stressing structural steel bar with the advantages of high strength, low relaxation rate, good welding performance, convenient and reliable connection, easy tensioning construction, etc., the high-strength rebar is widely used in the construction of large-scale water conservancy projects, continuous beams and large-scale frame structures in industrial and civil buildings, large-span bridges of highways and railroads, nuclear power plants and suspension bridges with the main cables in ground anchors, etc., as well as in the construction and anchoring of the rock body.

Diameter: Φ28~Φ100mm

Strength grade: PSB930~PSB1080

Reference standard:

GB/T20065-2016 Threaded steel bars for prestressed concrete

High-strength prestressing rebar is divided into levels by yield strength, and its code is "PSB" plus the minimum value of yield strength, P, S, B are the first letters of Prestressing, Scres-thread, Bars, etc. For example, PSB830 indicates that the standard value of yield strength is 830MPa. For example: PSB830 indicates that the standard value of yield strength is 830MPa rebar.

Mechanical Properties of High Strength Prestressed Rebar

level Yield strength Yield Strength

Rp0.2

MpaTensile strength Tensile strength

Rm

MpaSevered elongation Rate

A %Maximum force Total elongation

Agt %Stress relaxation properties Not less than Initial stress Stress after 1000h

Relaxation rate Vr/%PSB78578598083.50.8Rp0.2≤4.0PSB83083010307PSB93093010807PSB1080108012306High Strength Prestressed Rebar Size

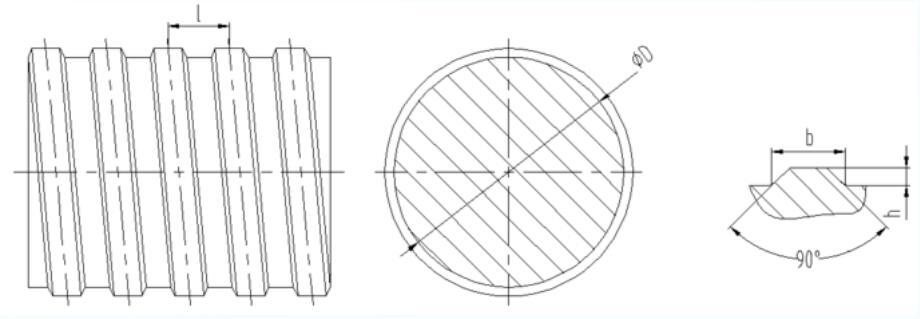

Base circle diameter D

mmThread height h

mmThread bottom width b

mmPitch l

mm653122270312227531222803.51224 853.51224 903.51224 953.51224 1003.51224 1103.51224 1203.512 24 1303.512 24 Note: Special customization is available upon request.

Want to learn more about the protuct?